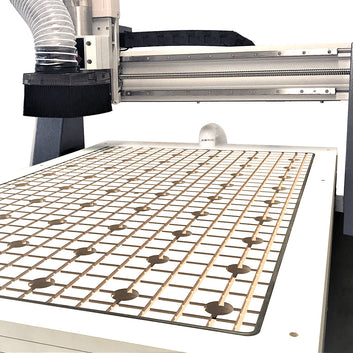

Custom made in Australia, these Vacuum Tables provide an elegant and efficient solution for workholding on CNC machines. While traditional clamps can be used, their placement must be precise to avoid collisions with the cutting bit, spindle, or clamps. Vacuum Tables are particularly well-suited for flat sheet work and are a great upgrade for small-format CNC machines, including the i2R A Series and i2R B Series, as well as other compatible models. Note that Vacuum Tables are not designed to hold individual small parts unless the part maintains sufficient surface area for vacuum hold-down.

Vacuum Tables generate a hold-down force based on the pressure difference between the vacuum beneath the part and atmospheric pressure. The larger the exposed surface area, the stronger the hold-down force. An MDF spoilboard can be placed on top of the table to protect the vacuum table from overcut while still allowing vacuum suction to pass through. Be mindful that permeable materials or excessive through-holes may reduce vacuum efficiency.

Normally, the Vacuum Table replaces the standard MDF spoilboard included with the machine, ensuring no loss of travel or clearance. The table provides 150mm of Z-axis travel and additional clearance, with a 32mm depth and a 4mm MDF spoilboard.

Key Features:

- Custom-made in Australia for small-format CNC machines

- Ideal for flat sheet work, delivering a secure hold without traditional clamps

- Compatible with i2R A Series, i2R B Series, and other small CNC routers

- Uses vacuum pressure to generate hold-down force, proportional to surface area

- MDF spoilboard can be added to protect the table while maintaining vacuum efficiency

- Preserves full Z-axis travel and clearance with a 32mm table depth and 4mm MDF spoilboard